We've come up with the following reasons as to why robotics in warehouses could be beneficial to you and your business.

We've come up with the following reasons as to why robotics in warehouses could be beneficial to you and your business.

Robots can pick in places humans typically cannot

One of the greatest benefits of using robots in your warehouse is having them execute tasks that humans cannot perform. This includes getting into smaller or less accessible spaces. With robotic technology in your warehouse, you can build your shelving higher and closer together if you use robots over traditional forklifts. They can complete more dangerous or menial tasks that humans are not able to do, which helps keep your employees safer and more engaged. Consider this a partnership of humans and robots, not a replacement of humans.

Robots are highly efficient and can pick and move faster and make better use of the space in your warehouse

Meeting the demands of e-commerce consumer expectations of quick order-to-delivery times can be quite a challenge.

Meeting the demands of e-commerce consumer expectations of quick order-to-delivery times can be quite a challenge.

Robotics can help circumvent these challenges and increase productivity by increasing the speed of how long a task takes and handling much larger volumes of goods per day.

They can perform for extended periods which means order fulfilment can be expedited to keep up with demand. Robots are programmed to do exact tasks, without wasted time in movement.

Robots are extremely accurate and reduce picking and packing errors

While robots are not a replacement for human intuition, creativity, adaptability and dexterity, their accuracy is a huge benefit when it comes to robotics in the warehouse. This is especially important for ensuring fewer mis-picks and errors, which can decrease productivity and consumer trust.

Robots alleviate the headaches of human staffing in the warehouse

Robots alleviate the headaches of human staffing in the warehouse

With the current challenges of a decreased labour pool and increase in minimum wages, adding robotics to a warehouse ensures that a warehouse is staffed to perform without the challenges of an actual workforce. While robotics are a large upfront investment, they do reduce the costs of staffing over time.

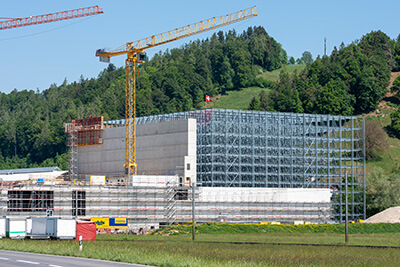

Optimise your warehouse with robotics and automation

Dexion can provide warehouse spaces with our semi-automated products like Pallet Shuttles, Vertical Lifts and Mobile Racking solutions, or work with our integrators on fully-automation projects such as Rack Clad, Inhouse pallet automation and Mini Load systems. With these cost-friendly and efficient solutions you can maximise your storage space with smart warehouse designs and automation. Talk to us to discover more.